Prevention of bristle loss through our unique manufacturing process.

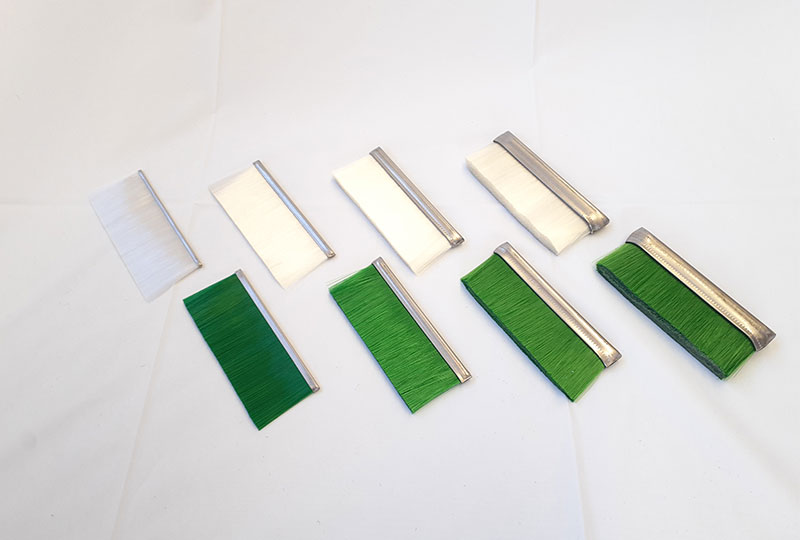

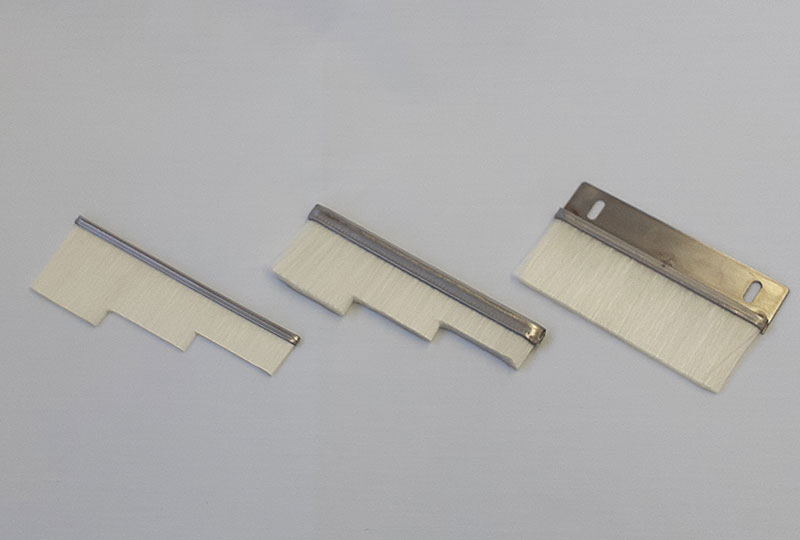

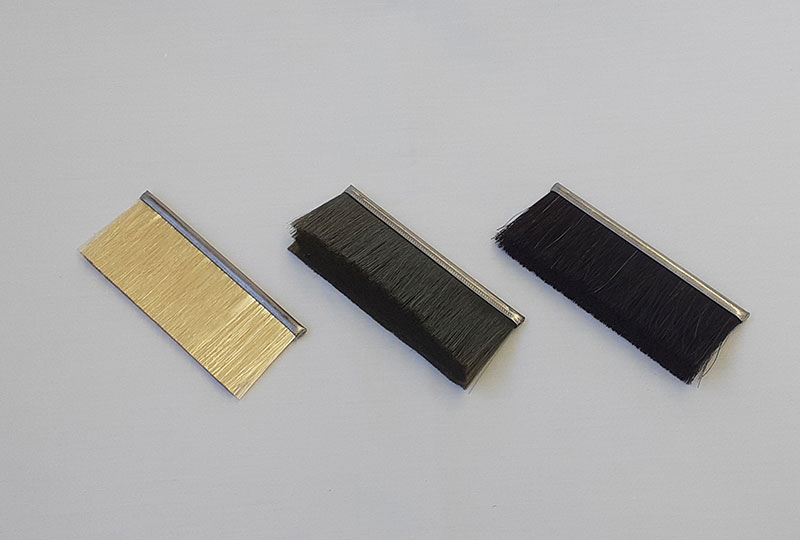

1.Straight brushes

A straight brush with bristles fixed by sandwiching them between channels (steel plates).Custom-made brushes that allow selection of channel size, bristle type, wire diameter, and dimensions.

Applications

Cleaning, Washing, Polishing, Masking, Static elimination, Coating

Use Cases

- Covers for equipment to prevent dust and scatter, application of liquid agents using brushes, and dust collection.

- Oil mist prevention cover

- Small animal intrusion prevention guard

- custom covers for various equipment and specialized machines

- Foreign matter intrusion prevention

- Shielding of wiring openings

Feature

Achieves excellent durability through a unique manufacturing process.

The size of the channel allows for the selection of fiber density.

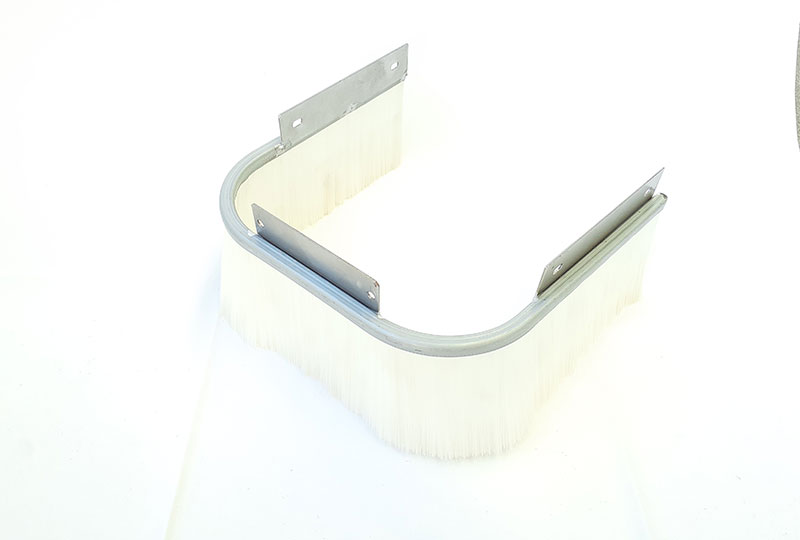

We can prepare mounting brackets tailored to the dimensions of the equipment, as well as accommodate bending processes, allowing us to manufacture according to specifications suitable for your needs.

Linear brushes can be processed into coil or cup shapes, making them applicable to various types of brushes.

For deburring, polishing, cleaning,

and washing of inner surfaces of small diameter holes and intersection areas.

2.Twisted Brushes

A Brush in which bristles are arranged between the core wire and twisted to secure the bristles.Effective for brushing inner diameter surfaces.

Used in a wide range of applications, from manual work to machining.

Applications

Cleaning, Washing, Polishing, Deburring

Use Cases

- Cleaning and washing of the interiors of pipes and tubing.

- Deburring of the inner surfaces of small diameter holes and intersecting holes.

- Removal of burrs from inner diameter intersecting holes in frames.

- Cleaning and polishing of the inner surfaces of threaded holes.

- Interior cleaning of precision glass and similar materials.

Feature

Brushing is possible in hard-to-reach areas, such as small diameter holes.

Customization is available to specify the brush outer diameter, length, and material.

We offer optimal specifications through four manufacturing methods, including new products.

- ①Double spiral-type (W/S )

A brush that satisfies both density and durability by alternately twisting bristles with four core wires. - ②Double single spiral-type (S/S)

A durable brush in which bristles are twisted with two core wires. - ③Single spiral-type (S)

A cost-effective brush in which bristles are twisted between two core wires. - ④SF Twisted Brush [New Product]

By folding back the bristles with a single straight wire twist, soldering at the tip is unnecessary.

Compared to conventional twisted wire brushes, it holds a greater amount of fibers at the tip, making it effective for brushing the bottoms of holes.

When used as a rotary tool, it is manufactured to match the rotation direction of the power source (CW/CCW).

The bristles section can also be processed with multi-stage cutting or taper cutting suitable for the shape of the workpiece.

Efficiently cleans, polishes, deburrs, and buffs into every corner.

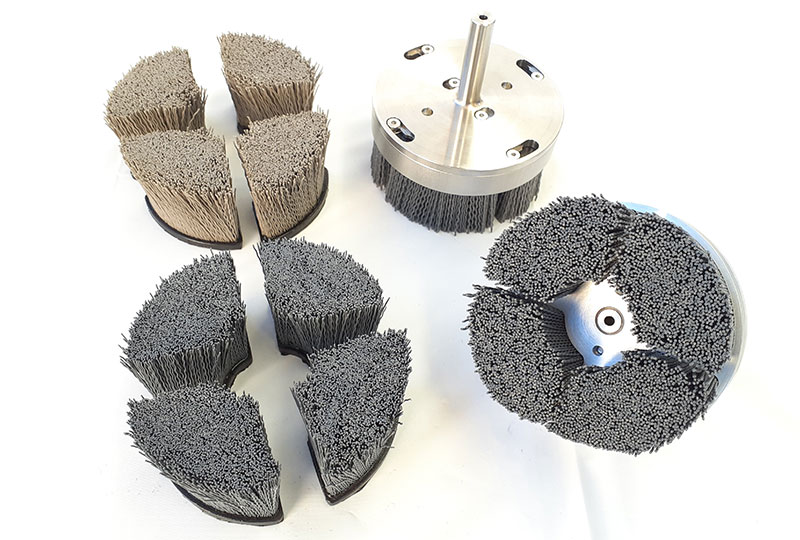

3.Cup Brushes

Cup-shaped brush with fibers arranged in the direction of the drive shaft.It allows for efficient brushing over a wide area from a vertical position.

Applications

Cleaning, Washing, Polishing, Deburring

Use Cases

- Floor cleaning, Washing and polishing of large work surfaces, Deburring

- Removal of scale such as spatters after welding.

- Removal of adhesives and other contaminants.

Feature

In addition to channel type, press type, and dot type, you can select the optimal specifications from four manufacturing methods, including the new product, the punch brush.

- ①Channel Type

Channel size and volume of bristles can be freely selected. - ②Press Type

Brackets compatible with the mounting standards of electric and pneumatic tools can be selected. - ③Dot Type

By using a discontinuous bristle arrangement, a cutting effect that conforms well to the shape of the workpiece is achieved. An adjustable bristle length mechanism can be added, allowing for adjustments to brushing intensity. - ④Punch Brush [New Product]

A high-density lightweight brush with excellent cost performance that eliminates waste. Compared to traditional channel types, this brush achieves weight reduction by securing the bristles with resin. The brush section is a high-density type with bristles evenly distributed. Since the protrusion length of the bristles can be adjusted, it allows for customization of the optimal brushing intensity. Worn brushes can be easily detached from the holder, allowing customers to replace them effortlessly.

Three types of winding methods to choose from based on your needs.

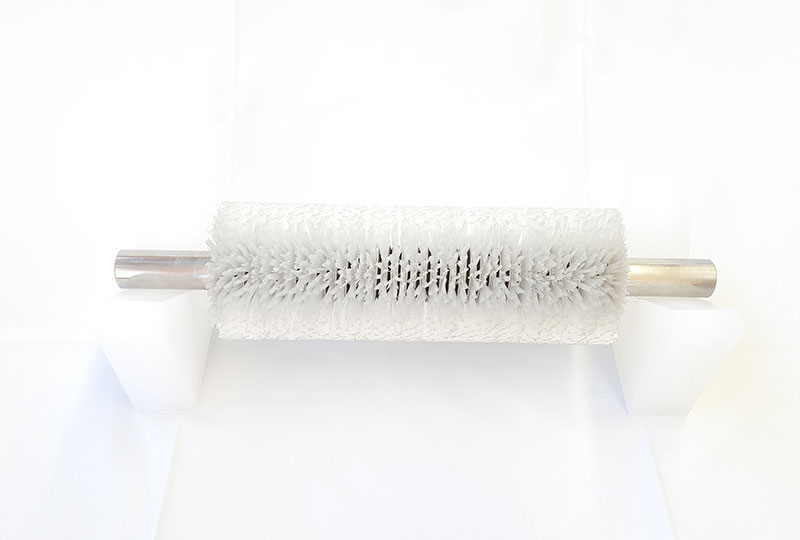

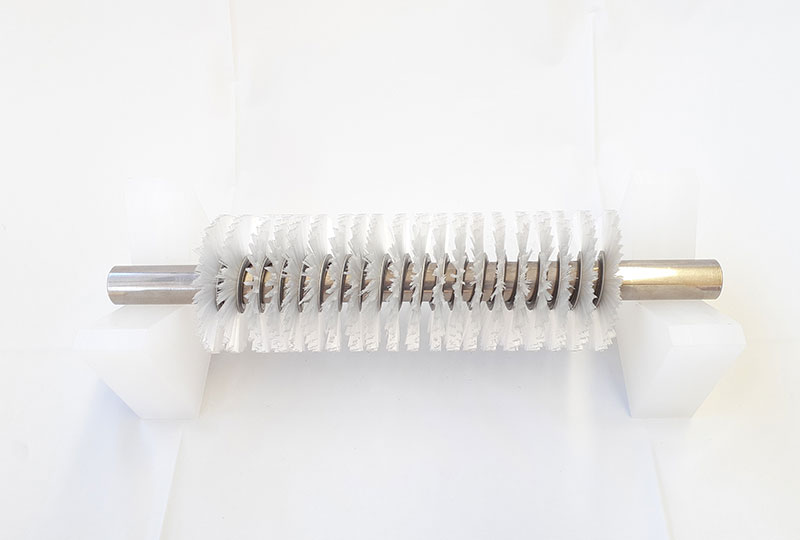

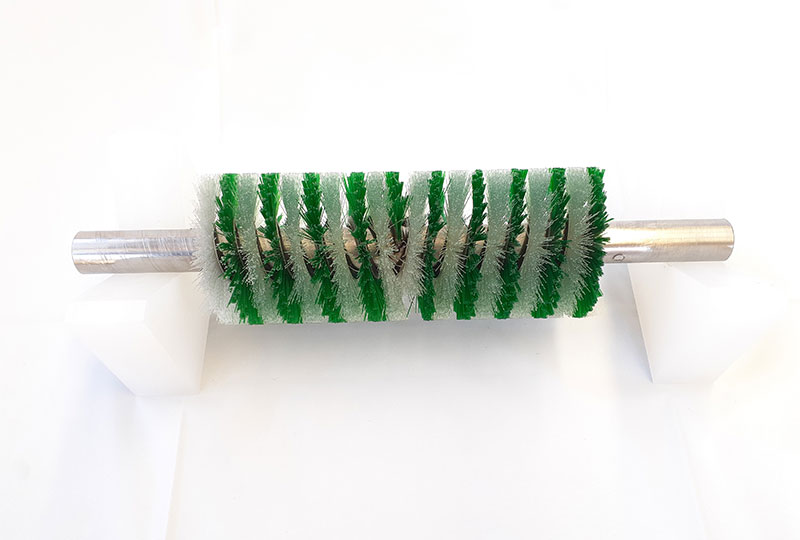

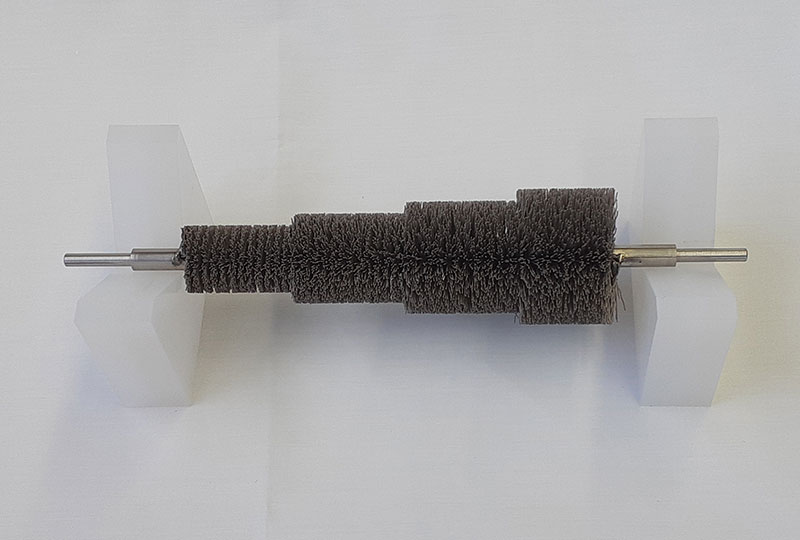

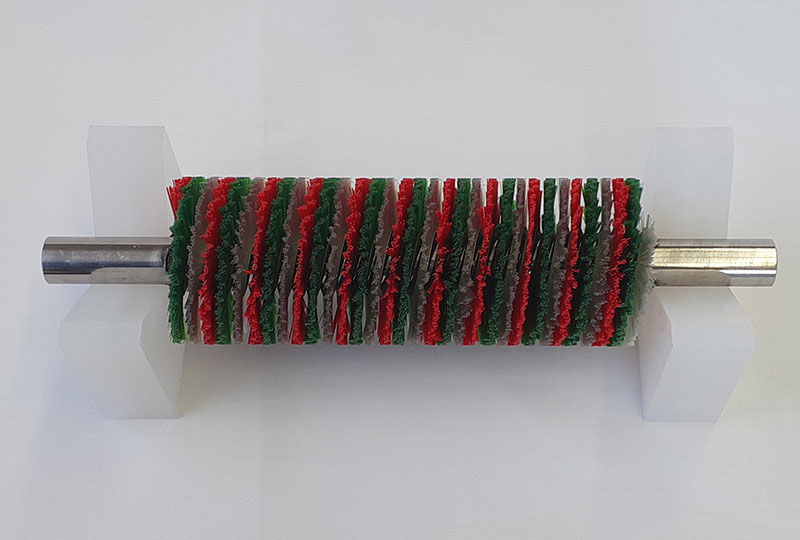

4.Roll Brushes

Spiral brush with a linear brush wound around a shaft or core.By spacing the brush windings, the density of the fibers can be freely controlled.

Applications

Cleaning, Washing, Polishing, Deburring, Static Elimination, Coating, Conveying, Usage example

Use Cases

- Various cleaning machines and polishing machines, used in a wide range of production lines from the steel industry to the LCD and semiconductor industries.

- Cleaning of various trains include blue train (Shinkansen).

- Cleaning of conveyors in various FA lines.

- Cleaning and dewatering of the canvas and felt in paper machines.

- Dust removal in tile manufacturing.

Feature

With three manufacturing methods suitable for the application, dimensions, bristle types, and densities can be freely selected.

- ①Close winding: A high-density brush with bristle wound tightly without any gaps.

- ② Pitch winding: A brush wound with spacing between the bristle, unlike close winding. It can also be used for conveying applications where density adjustment and pitch are advantageous.

- ③Helical winding: A brush wound in opposite directions from the center, which pushes the object to the left and right during rotation.

In addition to the above, radial types and multi-row types are also available.

Can be manufactured up to a total length of 6.4 m and a brush outer diameter of Φ1100.

Can accommodate dynamic balance adjustments and special bristle trimming.

Since the shaft can be reused, the used brushes can simply be replaced with new bristles.

- ・High-Precision Cleaning Brushes

Roll brush for precision applications.

Rotational runout accuracy: within 0.3. Brush outer diameter accuracy: ±0.25.

We can handle cleaning in our own cleanroom. Products will be delivered while maintaining cleanliness. - ・Cartridge Brushes [New Product]

By incorporating an anti-rotation mechanism in the brush section, welding for fixation is unnecessary, allowing customers to replace the brush themselves. This eliminates the need to send the brushes back to our factory for regeneration, contributing to reduced packaging work and transportation costs.

Compact with a high bristler density, offering excellent workability and durability.

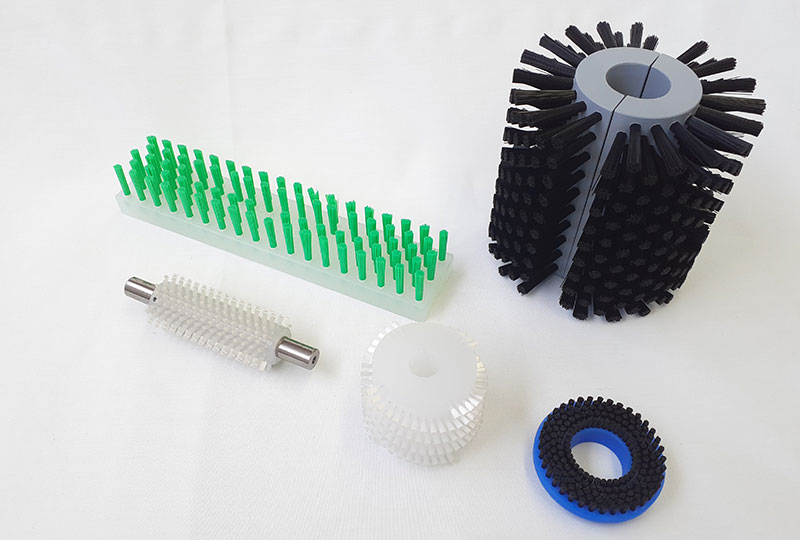

5.Coil brushes

Brush made by winding a straight brush into a spiral shape.Compared to twisted brushes, a higher bristle density allowing for greater brushing effectiveness.

Applications

Cleaning, Washing, Polishing, Deburring, Static Elimination, Coating, Conveying

Use Cases

- Cleaning and scrubbing of inner surfaces and small areas, surface polishing, deburring, and spatters removal.

- Deburring of bolts or nuts, and others

Feature

With two manufacturing methods tailored to different use cases, you can freely choose the dimensions, fiber types, and densities.

- ①Close winding: A high-density brush wound tightly without any gaps.

- ②Pitch winding: Unlike close winding, this brush is wound with spacing between the bristles. By adjusting the pitch, density can be modified.

By using a replaceable holder, it is possible to exchange only the brush.

Enhanced dust-proof effect

6.Inner coil brushes

A brush with bristle wound spirally inward.A high-density and fine brushing effect unique to the channel manufacturing method.

By selecting the channel size and fiber type, it is possible to choose the optimal effect suitable for the application.

Applications

Cleaning, Washing, Polishing, Deburring, Static Elimination, Coating, Conveying, Dust removal

Use Cases

- Cleaning and lubrication of the outer surfaces of shafts and similar components.

- Polishing and deburring, etc.

- Sealing function of the rotating shaft.

Applications

- ①Close-Wound: A high-density brush wrapped tightly without any gaps.

- ②Pitch-Wound: Unlike close-wound brushes, these are wrapped with gaps in the pitch, allowing for density adjustment.

By using a replaceable holder, only the brush can be exchanged.

High-density, high-balance power brush

7.Wheel brushes

Brush with bristles arranged on the outer circumference, similar to a roll brush.Widely used from electric tools to machining.

High density allows for high brushing effectiveness.

Applications

Cleaning, Washing, Polishing, Deburring, Static Elimination, Coating, Conveying

Use Cases

- Cleaning, burr removal, surface finishing, paint stripping, and substrate preparation of steel materials and similar items.

- Resharpening cutting tools and removing welds from rake surfaces.

- Removal of pin corners from metal parts.

Feature

Thinning plate (flange) , which allows strength to be maintained through a single-stage drawing process.

Lightweight structure that reduces the burden on the drive source and other components.

Allows adjustment of the required brush width by using a single unit or stacking multiple units together.

Polishing and deburring in narrow areas

8.Cylindrical brush・Umbrella brush・Flat brush

It is effective for brushing in narrow areas such as inner diameters and bottoms.Can also be used with power tools

The new product, the octopus brush, is a cost-effective replaceable cylindrical brush that eliminates waste.

Applications

Cleaning, Washing, Polishing, Deburring,

Deburring of motor input shafts and gear reduction gears

Use Cases

Cleaning, washing, polishing, and deburring of the inner diameter of pipes and the bottoms, corners, and sides of small holes.

Feature

Depending on the application, you can select the optimal specifications from three different shapes.

- ①Cylindrical Brush: A brush with bristles planted axially, designed for brushing the bottom area.

- ②Umbrella Brush: A brush with bristles spread in an R shape or cylindrical shape, intended for brushing the intermediate joint.

- ③Flat Brush: Brush with bristles spread laterally, aimed at brushing the corners of the bottom area.

- ・

TAKO Brush [New Product]

Conventional cylindrical brushes had to be discarded after use. The TAKO brush, however, uses a holder that allows only the brush part to be replaced, making it possible to reuse the holder.

Cost reduction is achieved by fixing the bristles with a pipe structure.

Since the protrusion length of the bristles is adjustable, it allows for optimization of the brushing intensity.

Effective for deburring narrow areas and bottom edge.

Brushed bristles planted in wooden or synthetic resin brush bases.

9.Implanted brushes

Brush made by winding a straight brush into a spiral shape.Compared to twisted brushes, a higher bristle density allowing for greater brushing effectiveness.

Applications

Cleaning, Washing, Polishing, Deburring, Static Elimination, Coating, Conveying

Use Cases

Various cleaning and polishing applications. Selected when there is a need to increase the power of the drive source.

Edge polishing of semiconductors and multilayer substrates.

Feature

Both hand planting and machine planting are possible.

The amount of bristles, pitch, and bristle patterns can be produced in various configurations.

In the case of roll shapes, they can be easily replaced by splitting them in half.

Since we perform cleaning in our own clean room, we deliver products while maintaining cleanliness.

Simple easy-to-use handy brush

10.Standard Brushes

Easy-to-use handy type brush.Choose from a broad lineup.

We also accommodate production in dimensions and bristle materials that are not included in the lineup.

Applications

Cleaning, Washing, Polishing, Deburring, Static Elimination, Coating, Conveying, etc.

Use Cases

Cleaning of various materials, rust removal from metals, and spatters removal, among others.

Feature

It is effective for a wide range of tasks, such as maintenance of machines and tools, as well as unexpected rust removal work. The replaceable brush part contributes to cost-effectiveness.

Road-related cleaning and washing

11.Road Sweeper

Brushes for cleaning and washing roads and similar surfaces.We offer a lineup of standard sizes from various street sweeper manufacturers.

Active in infrastructure maintenance-related activities.

Applications

Cleaning, Washing

Use Cases

Designed for cleaning and washing surfaces such as roads, guardrails, tunnels, and sound barriers. Additionally, it is useful for removing weeds along roadways

Feature

Flat steel wire side brushes, center deflector brushes, and others.

We also handle some components other than brushes, such as skid bars and dirt shoes.

Various arrangements are possible, unique to a specialized manufacturer of industrial brushes.

Suitable for all surfaces, from circuit roads to airport runways, ensuring reliable performance.